|

New Forum Bugs, Updates

Post any bugs or annoyances here. This will be deleted when the forum is back to normal. Thank You! |

83 Posts |

Last post by drhardin |

|

General RGG Guns/ Homebrew gats

Home built Gat gun discussion, Q&A, New member intro |

925 Posts |

Last post by Dave |

|

Progress

Show off your build progress and guns here. Even if its a pile of rods and bars..... |

2218 Posts |

Last post by Hunter bill |

|

D&E Specific

A Place for D&E specific guns |

510 Posts |

Last post by Hittman |

|

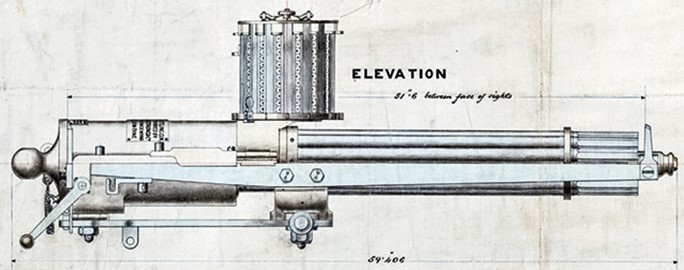

Original Guns

Reference pics |

33 Posts |

Last post by Cutter |

|

Machining

Machining discussion, tools, machines, tips and tricks. Post any machining related projects here |

495 Posts |

Last post by maccrazy2 |

|

Gunsmithing/Kit builds

Got ant other gun projects in the works? |

346 Posts |

Last post by bruski |

|

Q & A

Need technical help, have a drawing, set-up or any other question about building a Gat gun, post it here. |

479 Posts |

Last post by Richard Morton |

|

For Sale / Wanted / Trade

Post ANYTHING you want to buy, sell or trade. |

449 Posts |

Last post by Richard Morton |

|

Equipment

Machines, jigs, tooling. Work shop pics |

138 Posts |

Last post by dunn6902 |

|

Links

Links to great sites, metal working, guns, or anything you would like to share! |

15 Posts |

Last post by Larryx |

|

Break Room

Tired of making parts? Post anything off topic here, funnies, jokes. |

576 Posts |

Last post by Dave |

No New Posts

No New Posts Redirect Board

Redirect Board

6425 Posts in 713 Topics by 477 Members. Latest Member: Compton2000

Latest Post: "Re: Break the silence !" ( March 27, 2024, 08:31:53 AM )

View the most recent posts on the forum.

[More Stats]

52 Guests, 0 Users

Most Online Today: 82. Most Online Ever: 673 (January 22, 2020, 08:59:50 AM)

Gatlinggunforum - Info Center

Gatlinggunforum - Info Center